Since 1994, 3G has been providing shielding solutions for the most demanding applications. From simple Flex shields that have the best shielding effectiveness in the industry to 100 cavity plus Multizone shields or Hybrid shields that work at 5G frequencies, 3G has always innovated new techniques for shielding.

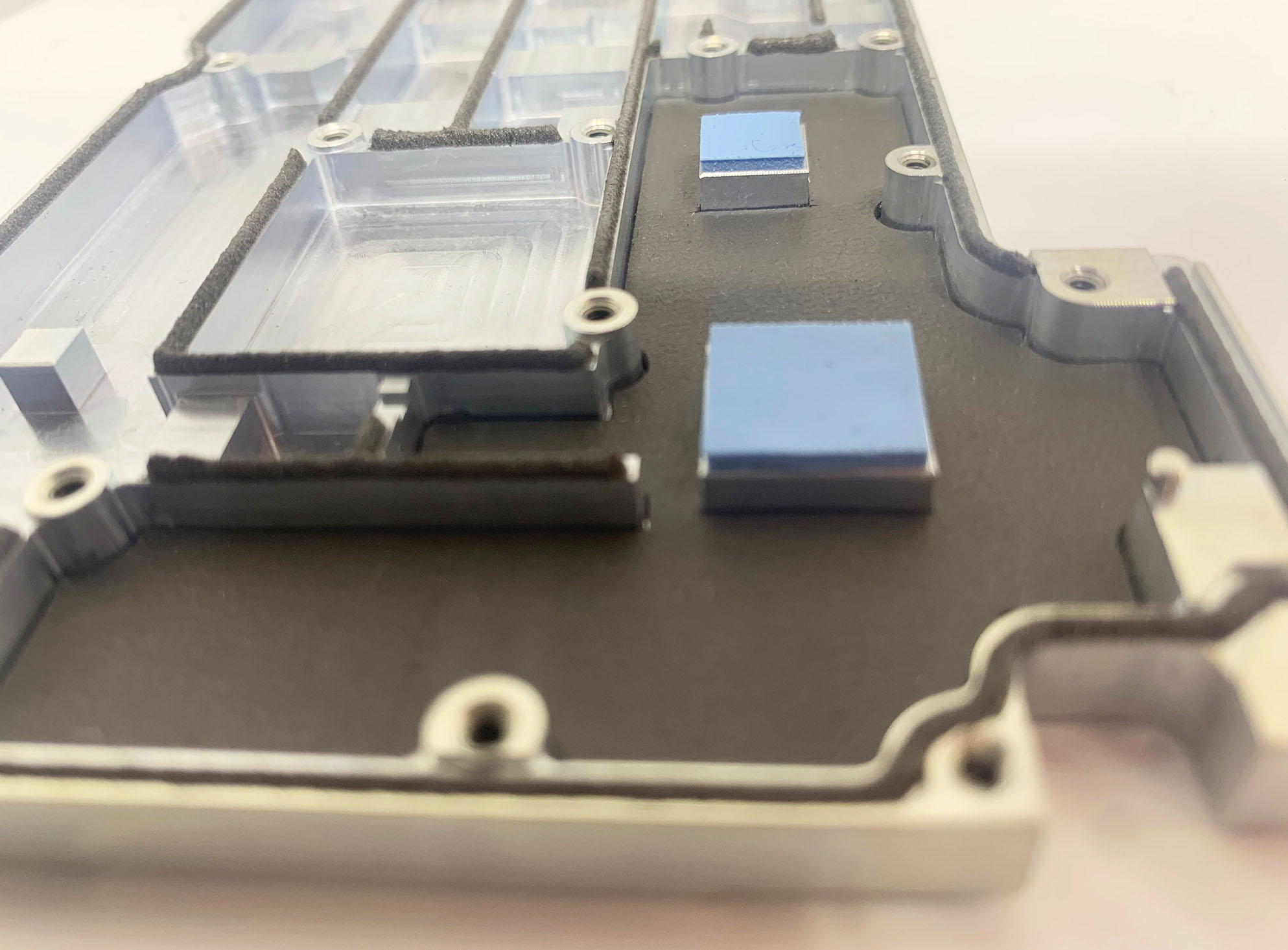

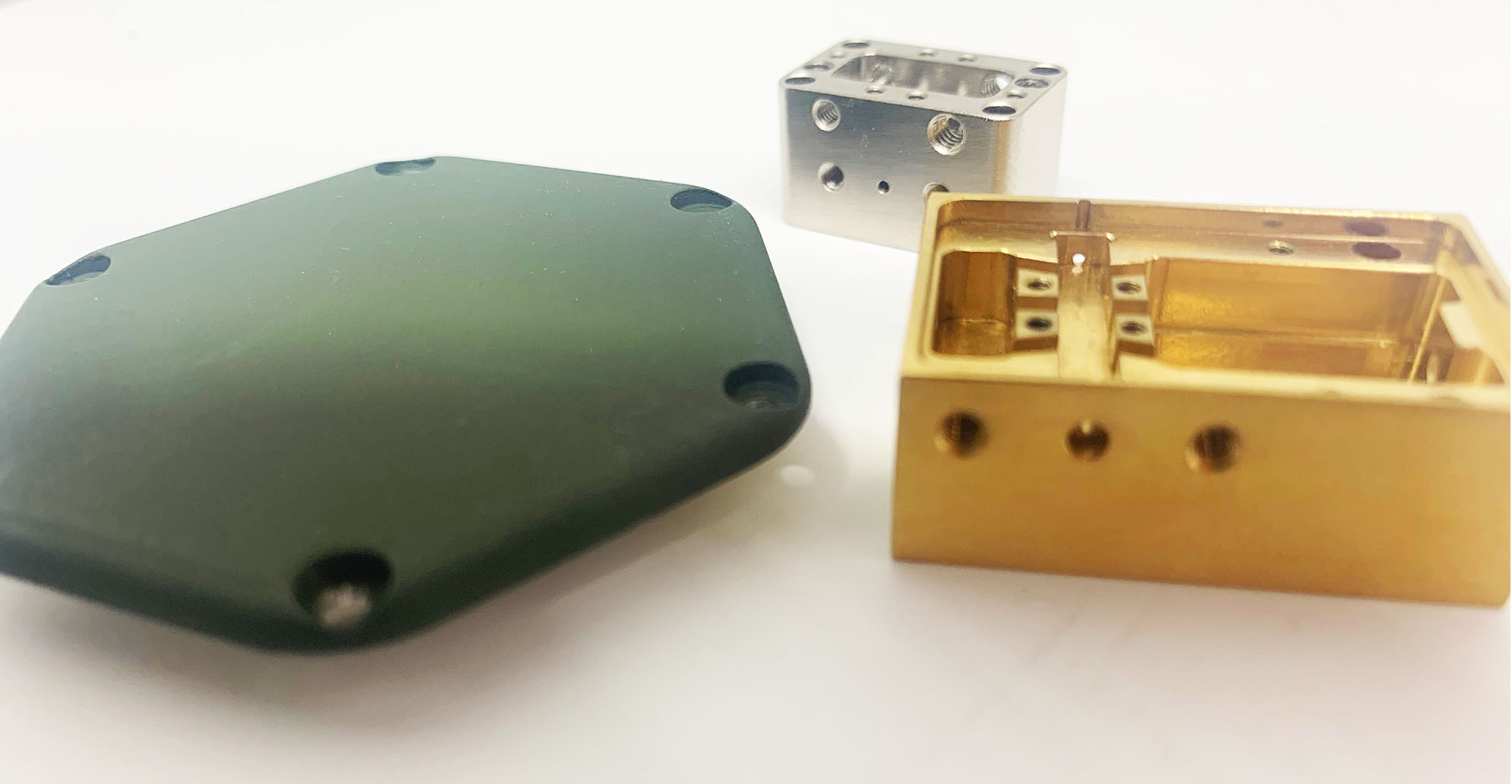

3G is now pleased to offer Machined Shields. Unlike traditional machining supply chain, 3Gʼs goal is to provide an integrated solution. 3G will assist with the design; provide required machining; ensure shields receive plating, painting, or other required finishes; dispense form in place gaskets or any other conductive elements; install thermal pads and absorbers. 3Gʼs Machined Shields provide an end-to-end solution.

Form In Place Gaskets

3G has a variety of Form In Place conductive gaskets ready to be dispensed. Our conductive materials are available with the following fillers:

- Ag/Al

- Ag/Cu

- Ag/Glass

- Ni/C

Thermal Interface Material and Microwave Absorbers

Where heat dissipation is a concern, 3G can cut and install ThermaWorx thermal pads in a variety of wattages and thicknesses to the machined shield.Where microwave absorbers are required, 3G can cut and install any of the 70+ Wavexorb materials we offer where required.

Materials and Finishes

3G offers Machined Shields in aluminum, brass, and copper. Cosmetic additions such as engraving or etching of logos and text can be included in designs at no cost. 3G offers chemical conversion coatings to MIL-DTL specifications along with anodizing in clear, black, blue, green or red. Machined Shields can also be plated with nickel, silver, gold, or tin. Epoxy paints and Powder Coat are also available along with silk screening to commercial or military specifications.

.jpeg)